Collection: JAPAN BLUE JEANS

There are things I want to cherish even if the times change.

We value the belief that "making jeans = making fabric".

It goes through all the processes of cotton selection, spinning, dyeing, sewing.

We would like to offer the joy of choosing jeans from materials centered around the world-class silhouettes and Japanese craftsmanship that have been acclaimed in the Western markets.

That is JAPAN BLUE JEANS starting from the fabric maker.

"Can you sell this?

At a French exhibition that I participated in every year as a denim fabric manufacturer, I saw the sample jeans I made to propose fabrics, and this word from an Italian designer gave me the opportunity to start JAPAN BLUE JEANS.

I was absolutely confident in the fabric, but my opponents were real American designers and professional buyers from all over Europe.

What is the silhouette that satisfies them?

Through repeated trial and error, we pursued uncompromising fabrics and silhouettes.

Our starting point is to make jeans that are polished to the aesthetics of the Western markets.

Passion for fabrics Stick to power loom

Selvedge , which is indispensable for vintage jeans, is a proof that it was woven on a vintage weaving machine called the old power loom (shuttle).

In order to weave denim that does not impair the characteristics of the material cotton and fits well to the body, and achieves natural and beautiful discoloration, it is essential to use an old power weaving machine that slows down the weaving without tensioning the threads as much as possible.

JAPAN BLUE JEANS continues to stick to this old power loom that disappeared due to mass production of denim, and at its own denim manufacturing factory, "TOYODA" automatic loom "GL-9" which was active in the early days of domestic denim 10 I am operating the table.

Weaving looms that have disappeared in modern times are completely out of stock.

Our denim fabric is woven by a dedicated craftsman who spends a lot of time talking and talking with the loom while carefully repairing each one.

Japan BLUE JEANS claims that this non-planar uneven denim is the real thing.

The key to making cotton dough is noodles

From the backbone as a fabric manufacturer, research and development from the blending of high quality cotton from various countries.

Originally spun yarn that matches the characteristics of each cotton in the world.

Original yarn that maximizes the goodness of cotton leads to a sense of presence and a sense of presence over the age of textiles.

From cotton to yarn

In order to bring out the individuality of the carefully selected cotton, the cotton is spun into threads and the rotational speed of mechanical parts called cams is adjusted in 0.1 second units to create a texture and uneven shape.

Cotton is an agricultural product, and the quality of the cotton is uneven every year.

We will fine-tune it so that it is as close as possible to the texture of constant quality.

By making unstable cotton as stable as possible, it will lead to dyeing and weaving after this.

Dyeing stick to the core white

The white core of the thread is essential for discoloring jeans.

This rope white can be made with Indigo's unique dyeing method called "rope dyeing" which dyes while touching the air.

At JAPAN BLUE JEANS, we have emphasized that rope dyeing affects the discoloration of jeans from the time of our founding, and we have made trials and errors of cotton, spinning, and weaving suitable for rope dyeing to create jeans that can enjoy various changes. going.

As a denim maker, we always research the latest dyeing technology and never forget our passion for innovation.

Aiming for the taste of domestic jeans at the dawn

We feel that the texture of domestic jeans in the 1960s, the unique twist of the hem and the sewn part, and the puckering are the tastes that have been born over the years, and we have made jeans important for long-term use.

Therefore, the vintage sewing machine made by "Union Special Co." that was used at that time is indispensable to our jeans.

In the latter half of the 1970s, domestic sewing machines became the mainstream and disappeared, but at JAPAN BLUE JEANS, existing sewing machines made by Union Special in Japan are scraped from the parts level, and real jeans are sewn by skilled craftsmen.

Silhouette recognized in Western markets

Since its launch, JAPAN BLUE JEANS has been planning for the Western market, and has many business partners all over the world.

At exhibitions around the world, we touched on the aesthetic sense of buyers from various countries and completed the world-class standard silhouette while taking advantage of the trendy trend of the reality of Europe and America.

From the combination of each silhouette and distinctive fabrics, we aim to create products that support the diversifying lifestyles of our customers and at times make them.

As a jeans maker that people all over the world can choose from, JAPAN BLUE JEANS faces every day directly in manufacturing.

We value the belief that "making jeans = making fabric".

It goes through all the processes of cotton selection, spinning, dyeing, sewing.

We would like to offer the joy of choosing jeans from materials centered around the world-class silhouettes and Japanese craftsmanship that have been acclaimed in the Western markets.

That is JAPAN BLUE JEANS starting from the fabric maker.

"Can you sell this?

At a French exhibition that I participated in every year as a denim fabric manufacturer, I saw the sample jeans I made to propose fabrics, and this word from an Italian designer gave me the opportunity to start JAPAN BLUE JEANS.

I was absolutely confident in the fabric, but my opponents were real American designers and professional buyers from all over Europe.

What is the silhouette that satisfies them?

Through repeated trial and error, we pursued uncompromising fabrics and silhouettes.

Our starting point is to make jeans that are polished to the aesthetics of the Western markets.

Passion for fabrics Stick to power loom

Selvedge , which is indispensable for vintage jeans, is a proof that it was woven on a vintage weaving machine called the old power loom (shuttle).

In order to weave denim that does not impair the characteristics of the material cotton and fits well to the body, and achieves natural and beautiful discoloration, it is essential to use an old power weaving machine that slows down the weaving without tensioning the threads as much as possible.

JAPAN BLUE JEANS continues to stick to this old power loom that disappeared due to mass production of denim, and at its own denim manufacturing factory, "TOYODA" automatic loom "GL-9" which was active in the early days of domestic denim 10 I am operating the table.

Weaving looms that have disappeared in modern times are completely out of stock.

Our denim fabric is woven by a dedicated craftsman who spends a lot of time talking and talking with the loom while carefully repairing each one.

Japan BLUE JEANS claims that this non-planar uneven denim is the real thing.

The key to making cotton dough is noodles

From the backbone as a fabric manufacturer, research and development from the blending of high quality cotton from various countries.

Originally spun yarn that matches the characteristics of each cotton in the world.

Original yarn that maximizes the goodness of cotton leads to a sense of presence and a sense of presence over the age of textiles.

From cotton to yarn

In order to bring out the individuality of the carefully selected cotton, the cotton is spun into threads and the rotational speed of mechanical parts called cams is adjusted in 0.1 second units to create a texture and uneven shape.

Cotton is an agricultural product, and the quality of the cotton is uneven every year.

We will fine-tune it so that it is as close as possible to the texture of constant quality.

By making unstable cotton as stable as possible, it will lead to dyeing and weaving after this.

Dyeing stick to the core white

The white core of the thread is essential for discoloring jeans.

This rope white can be made with Indigo's unique dyeing method called "rope dyeing" which dyes while touching the air.

At JAPAN BLUE JEANS, we have emphasized that rope dyeing affects the discoloration of jeans from the time of our founding, and we have made trials and errors of cotton, spinning, and weaving suitable for rope dyeing to create jeans that can enjoy various changes. going.

As a denim maker, we always research the latest dyeing technology and never forget our passion for innovation.

Aiming for the taste of domestic jeans at the dawn

We feel that the texture of domestic jeans in the 1960s, the unique twist of the hem and the sewn part, and the puckering are the tastes that have been born over the years, and we have made jeans important for long-term use.

Therefore, the vintage sewing machine made by "Union Special Co." that was used at that time is indispensable to our jeans.

In the latter half of the 1970s, domestic sewing machines became the mainstream and disappeared, but at JAPAN BLUE JEANS, existing sewing machines made by Union Special in Japan are scraped from the parts level, and real jeans are sewn by skilled craftsmen.

Silhouette recognized in Western markets

Since its launch, JAPAN BLUE JEANS has been planning for the Western market, and has many business partners all over the world.

At exhibitions around the world, we touched on the aesthetic sense of buyers from various countries and completed the world-class standard silhouette while taking advantage of the trendy trend of the reality of Europe and America.

From the combination of each silhouette and distinctive fabrics, we aim to create products that support the diversifying lifestyles of our customers and at times make them.

As a jeans maker that people all over the world can choose from, JAPAN BLUE JEANS faces every day directly in manufacturing.

-

JAPAN BLUE JEANS "J401" 14.8oz Denim CLASSIC STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J401" 14.8oz Denim CLASSIC STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J401" 14.8oz Denim CLASSIC STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "J301" 14.8oz Denim STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J301" 14.8oz Denim STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J301" 14.8oz Denim STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "J501" 14.8oz Denim LOOSE STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J501" 14.8oz Denim LOOSE STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J501" 14.8oz Denim LOOSE STRAIGHT

Regular price ¥18,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "J201" 14.8oz Denim TAPERED

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J201" 14.8oz Denim TAPERED

Regular price ¥18,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "J201" 14.8oz Denim TAPERED

Regular price ¥18,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS -CIRCLE- "J314" 14oz BLACK Denim STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS -CIRCLE- "J314" 14oz BLACK Denim STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS -CIRCLE- "J314" 14oz BLACK Denim STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS -CIRCLE- "J514" 14oz BLACK Denim LOOSE STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS -CIRCLE- "J514" 14oz BLACK Denim LOOSE STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS -CIRCLE- "J514" 14oz BLACK Denim LOOSE STRAIGHT

Regular price ¥20,000 JPYRegular priceUnit price / per -

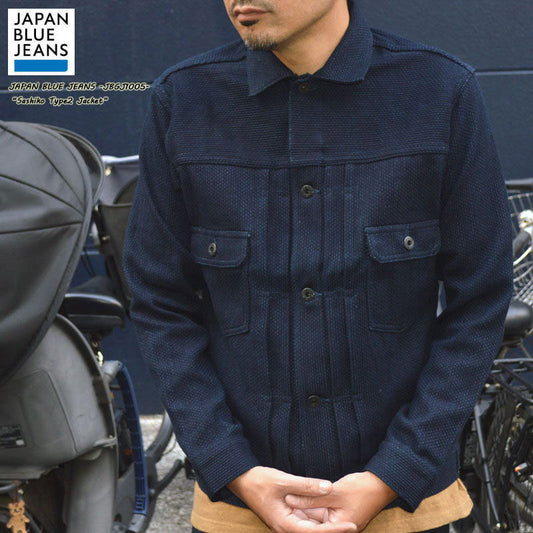

JAPAN BLUE JEANS "JBGJ1005" Sashiko Type2 Jacket

Regular price ¥32,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBGJ1005" Sashiko Type2 Jacket

Regular price ¥32,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBGJ1005" Sashiko Type2 Jacket

Regular price ¥32,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "JBJE1500" Sashiko Wide Tapered 5P

Regular price ¥24,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBJE1500" Sashiko Wide Tapered 5P

Regular price ¥24,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBJE1500" Sashiko Wide Tapered 5P

Regular price ¥24,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "JBSP1004" 11oz Indigo Sashiko Jaguard Tuck Shorts

Regular price ¥19,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBSP1004" 11oz Indigo Sashiko Jaguard Tuck Shorts

Regular price ¥19,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBSP1004" 11oz Indigo Sashiko Jaguard Tuck Shorts

Regular price ¥19,000 JPYRegular priceUnit price / per -

JAPAN BLUE JEANS "JBJE1417" 17oz Denim Classic Straight

Regular price ¥24,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBJE1417" 17oz Denim Classic Straight

Regular price ¥24,000 JPYRegular priceUnit price / perJAPAN BLUE JEANS "JBJE1417" 17oz Denim Classic Straight

Regular price ¥24,000 JPYRegular priceUnit price / per